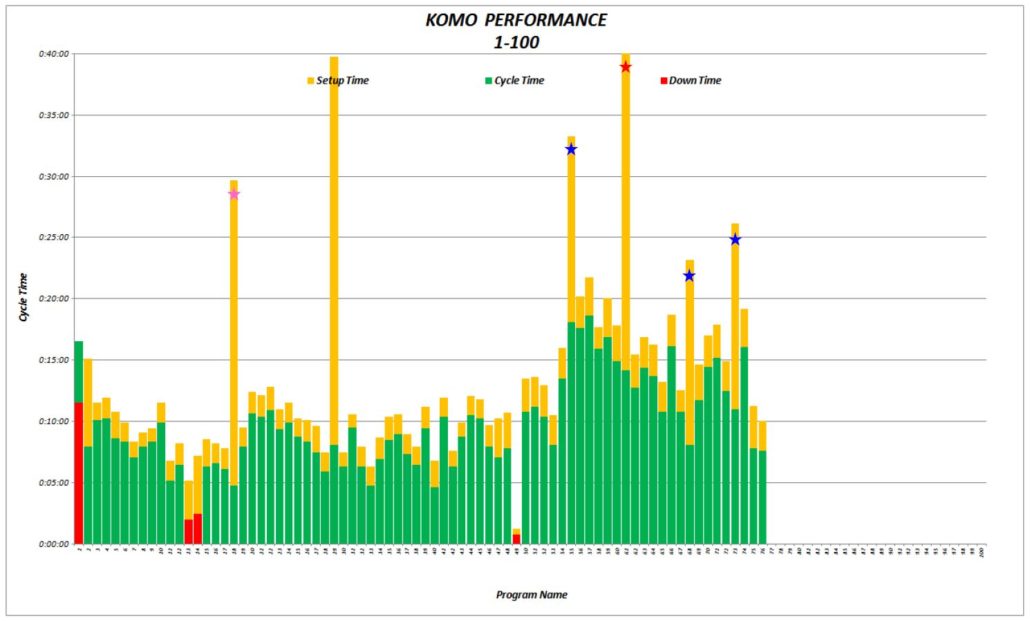

Every KOMO machine now ships with exclusive software that captures production data without any input from the operator. Specific events are recorded throughout the day, which are imported into a spreadsheet, analyzed and graphically displayed to identify problem areas. This software includes Tool Life Monitoring, which visually warns the operator as each tool nears the end of its life expectancy. Most importantly, operator safety is enhanced by configurable alerts sent immediately upon specific machine events.

KOMO Machine Monitoring

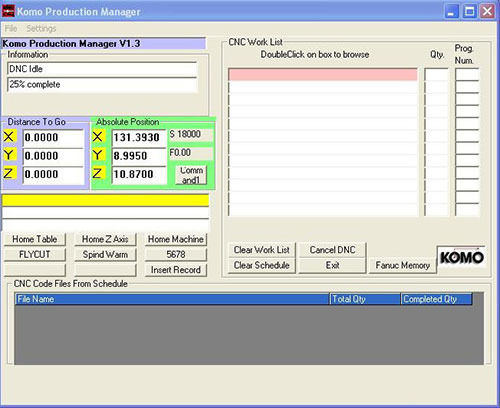

KOMO Production Manager Software

Each machine includes KOMO Machine’s exclusive Production Manager Software with Intelligent Spoilboard Management©. This productivity feature takes the guesswork out of managing your spoilboard, insures optimum performance of the flow-through vacuum system when nesting and provides a fast and efficient way to load your programs into your CNC Machining Center.

- Intelligent Spoilboard Management

- User-programmable buttons allow fast access to most commonly used programs

- Send programs to control memory in just seconds

- Ability to save partially run Schedule files due to production interruption

- Multiple file select and drag-and-drop support

- See your programs running on the control without switching screens

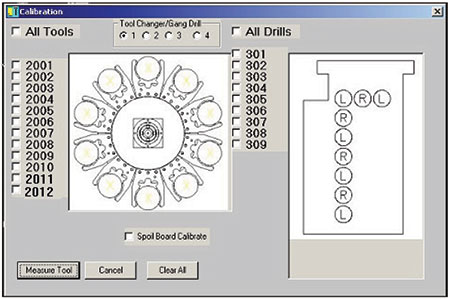

Automated Tool Touch System

For fast tool setup and high quality part finishes, KOMO offers an Automated Tool Touch System that takes the guess work out of calibrating your tools.

The quick and easy system allows you to setup your tools in one simple step. Decreasing downtime, increasing tool life and allowing for accurate tool configuration means more time producing parts.

The more time your machine is spent machining, the more productive your shop will be.