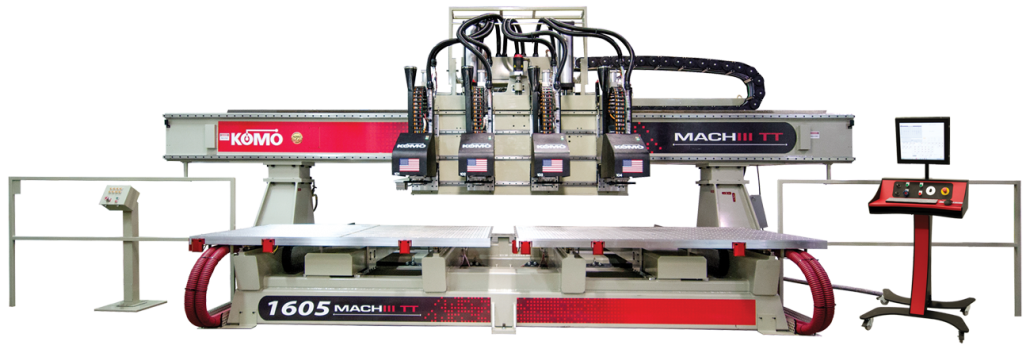

The Mach III Twin Table Series of CNC routers from KOMO Machine, Inc. has been developed specifically for the customer who requires a premier machine with more flexibility, more options and more Z travel than a Fusion Twin Table. These machines feature moving tables and a tool changer mounted on each spindle, and can be configured with multiple spindles, moulder heads, horizontal spindles etc.

Mach III Twin Table Series CNC Machining Center

Features

- Four-pole, 18HP (13.2kw), 24,000 RPM, HSK 63F, fan-cooled spindle (standard; other spindle options available)

- 15 position automatic tool changer with aggregate capability (optional additional 15 position tool changer available)

- Air blast for optimal dust/chip evacuation and cooling of the cutting tool

- Advanced Fanuc HVI servo system tuned for optimum acceleration and deceleration

- Tool touch-off device with automatic tool data uploading

- Fanuc Panel i control with integrated PC

- Precision machined aluminum table (2″) with options available

- Pressurized automatic centralized lubrication system

- Komo Production Manager with Intelligent Spoil Board Management

- 17″ touch screen display

Construction

- FEA “Finite Element Analysis” engineered structure

- Heavy-duty steel fabrication

- Closed-loop counterbalance system minimizes plant air consumption

Want to learn more about the Mach III Twin Table?

[form]

[yith_ywraq_button_quote]

MACH III TWIN TABLE SERIES CNC MACHINING CENTER

| Mach III Twin Table Technical Data | |

| Spindle | Quantity…..One standard, additional optional Type…..18HP (13.2kw), four-pole, fan cooled (standard) RPM…..Up to 24,000, fully programmable Taper…..HSK 63F |

| Table | 1005TT/1008TT…..(2) 60″ x 60″ (1524mm x 1524mm) / (2) 60″ x 96″ (1524mm x 2438mm) 1010TT/1012TT…..(2) 60″ x 120″ (1524mm x 3048mm) / (2) 60″ x 144″ (1524mm x 3658mm) 1605TT/2005TT…..(2) 96″ x 60″ (2438mm x 1524mm) / (2) 120″ x 60″ (3048mm x 1524mm) Four (4) 1″ (25mm) part location pins per table |

| Aggregate-Capable Tool Changer | Max Quantity…15 tools (per spindle) Max Diameter……3.25″ (82mm) positions full; 6.5″ (165mm) adjacent positions empty Max Weight….12 lbs each / 96 lbs total (5.4kg / 43.5kg) Max Length…..5″ (127mm) |

| Feed Rate/Traverse | X Axis…..3150ipm (80mpm) Y Axis…..3150ipm (80mpm) Z Axis…..600ipm (15.2mpm) Acc/Dec…..83 in/sec² |

| Axis Travels | 1005TT…..162″ (4114mm) x 80″ (2032mm) x 15″ (381mm) 1008/1010/1012TT…..162″ (4114mm) x 164″ (4166mm) x 15″ (381mm) 1605TT/2005TT…..258″ (6553mm) x 78″ (1982mm) x 15″ (381mm) |

| Control System | Fanuc Panel i…..With integrated PC and 17″ touch screen display |

| Dust Collection | Interface…..6″ (152mm) dia (1 spindle) recommended volume 900 cfm per spindle |

| Vacuum System | With low vacuum sensing interface |

| Options | Tooling Package…..Tool holders, collets, bench top tool changing block, wrench Vacuum Pumps…..Started via pushbutton on main operator panel, with remote start relay Boring Blocks…..Available in a variety of configurations, from nine to 25 spindles Part Labeling…..Print labels directly onto parts prior to machining Safety Equipment…..Laser scanners, light curtains, pressure mats Dual Screen…..Additional 17″ screen attached to the control allows for flexibility Metal Cutting…..Mist coolant, dust/chip enclosure, pressure foot for cutting non-ferrous metals C Axis…..Allows use of aggregate tooling, for four axis machining capability Table…..Aluminum universal grid, integrated pop-up roller balls Spindles.….Multiple spindles, programmable head spacing and/or shroud height, head locks |