Fanuc Controls for KOMO MACHINES

Komo proudly uses FANUC controls in all of their machines. As a FANUC Authorized CNC System Integrator, Komo is trained and supported by FANUC to do installs on new machines as well as system upgrades on legacy routers.

What do FANUC Controls Do?

KOMO Machine is a FANUC integrator and customizes these controls to be the "brain" of every CNC router. They process G-code instructions and coordinate all electrical and mechanical systems, including:

Amplifiers and servo motors work together via a program that is loaded into the controller. The controller sends the motion commands to the servo amplifiers for each axis and to the spindle amplifier. Amplifiers convert those commands into power for motors. The motors move the machine parts, and encoders provide feedback to ensure the machine follows the exact programmed path.

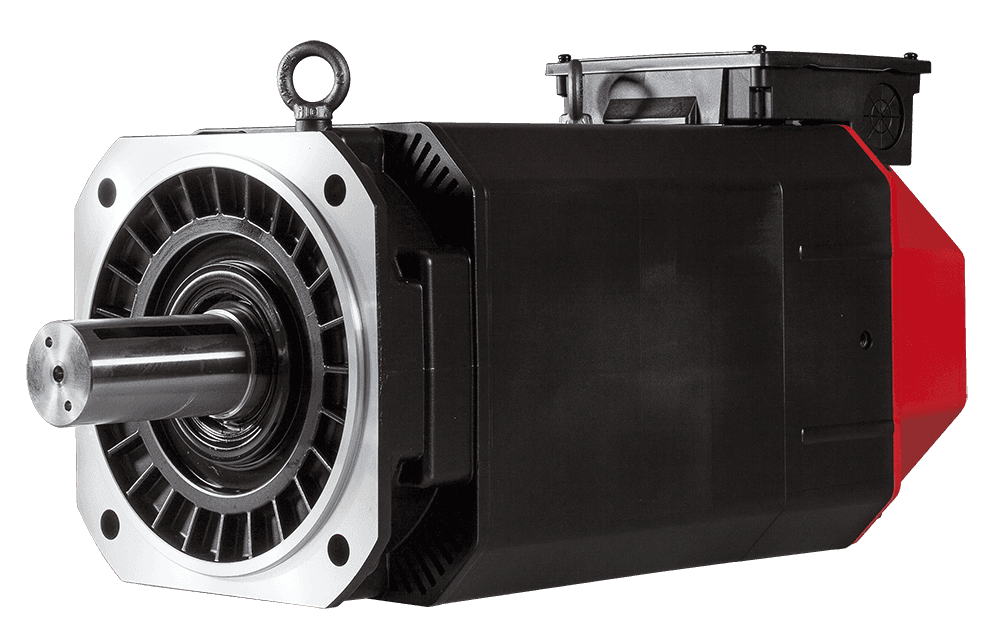

Spindle Amplifiers

The spindle is what holds and spins the cutting tool. The speed and torque of the spindle must be precisely controlled, especially for different materials and cutting strategies. There is a spindle motor that drives the cutting tool and a spindle amplifier that received commands from the FANUC control and converts these into precise voltage and current to control sprindle speed (RPM) and torque.

The amplifier gets feedback from the motor (RPM and torque) to adjust in real time. The benefits of this are smooth acceleration/deceleration, stable RPM under load and accurate speed control for specific materials and tools.

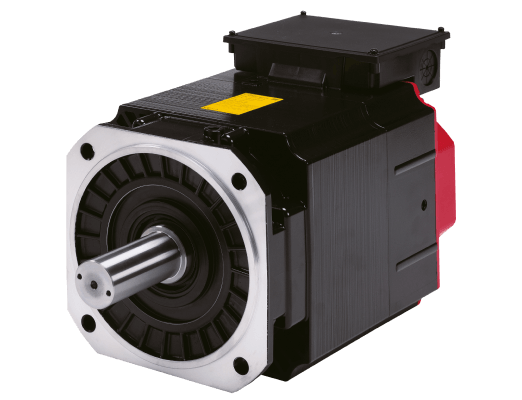

Servo Motors and Servo Amplifiers

Servo motors drive the X, Y, Z, and other axes, and are also used in the automatic tool changer. Their job is to move machine components with high precision and speed, and to maintain exact position under cutting forces. Each axis has a dedicated servo motor. FANUC controls precisely coordinate motion across all axes to follow a programmed path. Servos must synchronize perfectly to ensure clean cuts and avoid mechanical wear.

For the tool changer, FANUC control monitors the tool changer sequence to ensure safe, timed tool changes. Sensors and position encoders ensure the right tool is selected and properly seated.

How it all works together

| Component | Purpose | Controlled By | Key Role |

|---|---|---|---|

| Spindle Motor | Spins cutting tool | Spindle Amplifier | Cutting material |

| Spindle Amplifier | Controls spindle speed & torque | FANUC Control | Converts control signals to motor power |

| Servo Motors | Move axes, tool changer | Servo Amplifier | Precise motion and positioning |

| Servo Amplifier | Powers servo motors | FANUC Control | Executes motion commands |

| FANUC Controller | Central control unit | — | Orchestrates everything |

FANUC UPGRADES AND RETROFITS FOR YOUR KOMO MACHINE

In most cases, depending on the age and type of machine, an upgrade and retrofit will add continued operating life to your machine. Your Komo machine is built like a tank; structurally sound and mechanically capable of decades of service. Retrofitting with new controls (and routine maintenance) gives it a second life without the cost of a full machine replacement.

Older controls and components can become a maintenance nightmare with some older machines actually running on floppy disks and CDs. Modern systems are more robust and reliable, and easier to troubleshoot by KOMO technicians through remote diagnostics.

Updated FANUC controls are compatible with advanced CAD/CAM software, networking and IoT solutions. They feature modern user interfaces, touchscreens and better graphical displays. Furthermore, the latest-gen controls give you longer-term part availability, software upgrades and service support.

Upgrading your KOMO machine with modern FANUC controls turns a solid, older workhorse into a smart, high-performance production asset. It's a cost-effective way to modernize your operation, boost productivity and stay competitive in today's manufacturing environment.