Second Monitor (Dual Screen)

The dual screen option enables the operator to run the standard CNC touch screen on the HMI, while the attached 17″ touch screen can be used for viewing CAD Drawings, Real Time Tool View, Spindle Condition Monitoring, or any other Windows® application.

Available on these machines:

Spindle Conditioning Monitor

The Spindle Conditioning Monitoring Option is designed to monitor the vibration levels of the spindle as it is operating, and those levels are viewable from the machine control screen and can be fed to a remote office location. This allows an operator or production manager to know when a spindle is worn or overloaded – or being perfectly utilized.

Available on these machines:

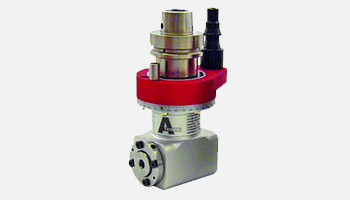

C-Axis

C-Axis allow you use of aggregate tooling, for four axis machining capability.

Available on these machines:

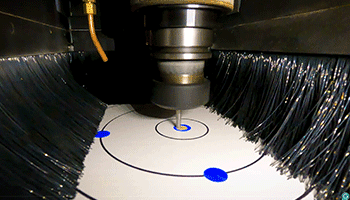

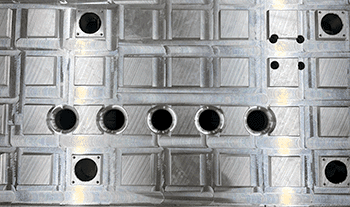

Multiple Vacuum Zones

All machines come with a 4" diameter high-flow vacuum manifold to ensure high vacuum transfer from the vacuum pump to the machine. Adding additional zones increases the holding power and stability of the workpiece.

Available on these machines:

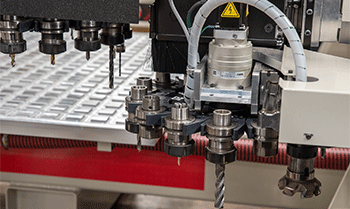

24-Pocket Static Tool Changer

Increase tooling capacity by choosing the 24-station tool changer, which takes the place of the standard 12-station tool changer

Available on these machines:

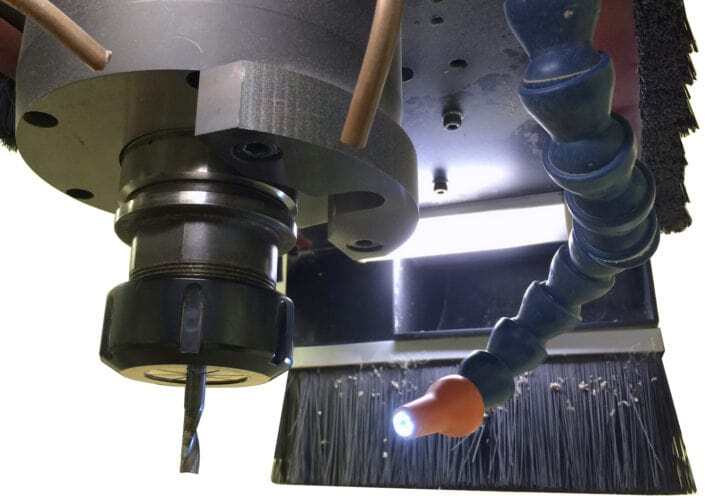

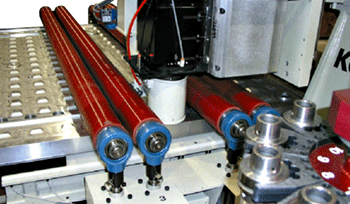

Roller Hold-Down

The Roller Hold-Down is designed to apply downward pressure to the workpiece so that it remains flat and in firm contact with the vacuum table. It is used with precision cutting of sheet goods.

Available on these machines:

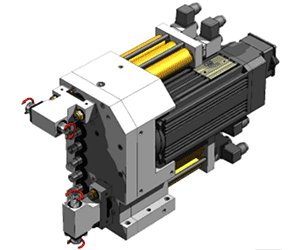

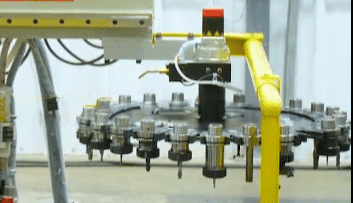

Independent Programmable Technology

KOMO’s Independent Programmable Technology (IPT) delivers complete flexibility via fully programmable center spacing as well as individual spindle feed, speed and axis control.

The spindles can be programmed to operate with complete flexibility. They can be slaved together to cut multiple parts simultaneously, or they can be split up to cut dissimilar parts on separate tables simultaneously.

Available on these machines: