KOMO Machine, Inc. offers a variety of standard and add-on safety equipment for your CNC Machining operations that can be configured to any specific model and application, including but not limited to those shown here. Contact Customer Service to purchase any of these safety devices

Standard Safety features for CNC Machining Centers

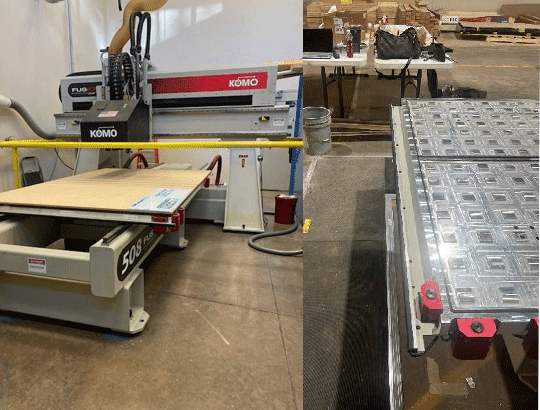

Gantry Guard - Single Table Machines

Gantry Guard - Twin Table Machines

The Gantry Guard provides a robust safety enclosure for single table traveling-table CNC machines. Constructed from durable steel tubing, this guard fully surrounds the work zone in front of the gantry, offering protection against the highspeed movement of the machine's head assemblies. The guard is fixed to the machine and includes an additional emergency stop button, allowing operators to halt the machine quickly in the event of a hazard. Its immovable design ensures a consistent level of protection, preventing unauthorized access to the work area while the machine is in operation.

Note: This standard feature is not compatible with the Material Handling System (MHS), so users should consider alternative options if the MHS is integrated into the workflow.

For twin traveling-table machines, the Gantry Guard offers similar safety features as the single-table version, with an added layer of protection. This guard is composed of steel tubing and surrounds the work zones of both the left and right tables. Each table has its own frame guard, ensuring comprehensive coverage. The system also includes an additional emergency stop button on one of the two guards. As with the single-table design, the gantry guard is fixed in place and offers critical protection against the high-speed motion of the machine's head assemblies.

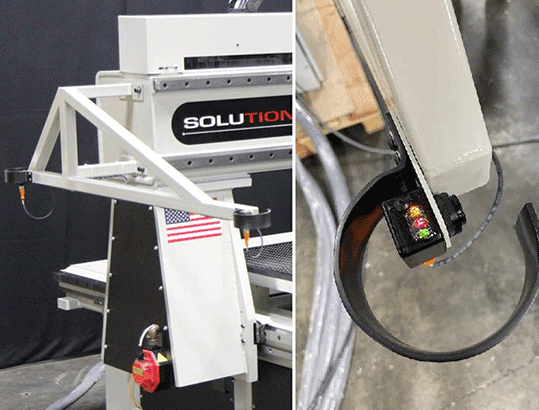

Safety Light Beam for Traveling Gantry

Safety Tape Perimeter

The Safety Light Beam system for traveling-gantry machines is designed to automatically halt the machine if any object disrupts the light beam. Comprised of two sets of emitter and receiver pairs, the system covers both the front and rear areas of the machine. As the gantry moves, the light beam moves with it, ensuring continuous monitoring. If the beam is broken, the machine will immediately enter feed hold mode, preventing further motion. To resume operation, the object must be removed, and the operator must clear the alarm on the Human-Machine-Interface (HMI).

The Safety Tape Perimeter is a high-visibility, yellow-and-black striped tape that marks the work zone surrounding the machine. This safety feature visually indicates the boundaries of the machine's active area, serving as a clear warning to operators and personnel to maintain a safe distance. The tape is adhered to the ground and provides a defined boundary for the work zone, helping to prevent accidental entry into potentially hazardous areas.

Optional safety features for CNC Machining Centers

Light Curtains

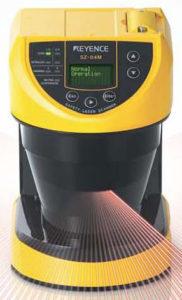

Laser Scanners

The Safety Light Curtain is an advanced safety feature designed to detect any obstruction in front of the machine. For single traveling-table machines, one set of light curtain components (transmitter, receiver, and reflectors) is installed to monitor the right, left and front sides of the machine. Twin-table machines utilize two sets of the light curtain kits, each covering one side and the front of bothe tables, allowing for pendulum processing mode. If the light curtain is disrupted by any object or person, the machine will enter feed hold mode, preventing further motion. To resume operation, the object must be removed, and the alarm cleared from the HMI. This system is the next level up for ensuring operator safety adn preventing machine damage dur to unintenional entry into the active work zone.

The Keyence Safety Laser Scanner System is an advanced optional safety feature that offers a large detection area for each unit, ensuring comprehensive coverage of critical zones around the machine. Its dynamic drawing function allows for the marking of specific areas for detection, enhancing the system’s flexibility. Multiple units can be incorporated to cover several zones simultaneously, making it ideal for complex machine layouts. The system’s target differentiation capability ensures that it can accurately distinguish between people or objects and non-hazardous items like dust, minimizing false alarms. Additionally, the system can be configured to record events, providing valuable data for safety monitoring. In the event that a person or object enters a designated detection zone, the system immediately activates the feed hold mode, halting the machine’s motion and preventing any potential accidents. To resume operation, the obstruction must be removed, and the operator must clear the alarm from the HMI, ensuring that the machine operates only in safe conditions.

Pressure Mats

Table Bump Strips

The Safety Mat System is an impact-resistant, pressure-activated safety feature designed to protect operators from injury during machine operation. The mats are strategically positioned around the machine on the floor to cover key areas of potential risk. For single traveling-table machines, the mats are placed in the front section surrounding the table. In twin-table machines, the mats are divided into two zones, covering the left and right sections of the front area. For traveling gantry machines, the mats cover the entire operator side of the machine. Whenever weight or pressure is detected on the mat, the machine enters feed hold mode to prevent further motion. Resumption of operation requires the removal of the obstruction and clearing of any alarms on the HMI. The mats can also be customized to fit multiple zones and sizes depending on specific customer needs.

The Table Safety Bumper Strips are pressure-sensitive strips mounted on both the front and rear of the table. These strips are encased in a durable elastomer to withstand impact. When the sensor strips come into contact with any object or person, the machine will immediately enter feed hold mode to prevent further motion. To resume the operation, the operator must clear the obstruction and reset the alarm through the HMI. This feature ensures quick and reliable halting of the machine when necessary.put text into the page.