Precision Manufacturing for Military Drones and CCAs

Map. Drill. Inspect. All inside the machine.

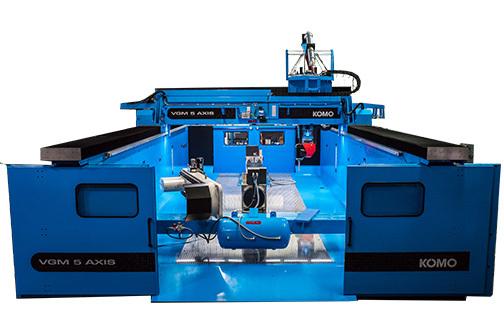

KOMO Machine delivers aerospace-grade CNC solutions that map carbon-fiber airframes, drill, and countersink precise fastener features, then generate traceable inspection reports, all within the machine’s operating envelope. Built for manufacturers of CCAs and UASs, our systems meet the throughput, repeatability, and documentation demands of military manufacturing programs.

BUILT FOR THE LEADERS IN DEFENSE MANUFACTURING

Manufacturers require production systems that combine composite-safe handling, tight tolerances, and defense-ready traceability. KOMO Machine CNC platforms integrate into those workflows, delivering a product that is assembly ready.

The Komo Machining System Provides:

- Complete part mapping of carbon fiber bodies to create an exact 3D surface model inside the machine.

- High-precision drilling and countersinking that respects fiber orientation and resin boundaries to prevent delamination.

- Automated inspection reporting (PPAP/FAI-friendly) produced directly from Komo’s operation package. No separate offline scanning required.

- Turnkey integration is all within the envelope of the VGM 5-Axis machine.

PRECISION BEGINS HERE — SIMPLE, ROBUST, VALIDATED

- Advanced surface scanning: The machine maps the composite body in situ, producing an accurate surface model that compensates for manufacturing variance.

- Program generation inside the envelope: Tool paths for drilling and countersinking are generated or verified against the mapped surface, all within the machine’s controls.

- Precision execution: High precision controllers and tools ensure holes meet aerospace tolerances without compromising composite integrity.

- In-machine inspection & reporting: Dimensional checks and countersink depth/angle measurements are captured and compiled into inspection packages (CSV/PDF/FAI formats) directly from the controller for secure data capture and downstream quality systems.

WHY KOMO FOR UAS & CCA PRODUCTION

- Aerospace-grade accuracy: Sub-0.005" repeatability and CNC motion control tuned for composite structures.

- Composite-safe process controls: Peck cycles, dwell strategies, and feed schedules optimized to protect fibers and reduce rework.

- Seamless quality documentation:Eliminate the manual handoff between machining and inspection; create auditable inspection reports automatically.

- Lower cycle times, higher yield: Integrated mapping and machining reduces setup time and scrap from poor hole placement.

- Defense program readiness: Designed for controlled environments, secured data export, and compliance with typical aerospace QA flows.

- Proven in the field: This mapping-to-machining workflow is already in production on Komo CNC machining centers at major military manufacturers and has delivered measurable improvements in throughput and traceability.

TYPICAL APPLICATIONS

Drilling & Countersinking

Structural fuselage/airframe drilling and countersinking for UAS and CCA skins.

Composite-to-Metal Fastening

Composite-to-metal fastening prep for blended structures.

Multi Panel Assembly

Multi-panel assembly alignment and fastener pattern verification.

High-Rate Production

High-rate production cells for tactical and long-endurance platforms.

KOMO Machine works with your engineering, quality, and production teams to deliver a complete solution

Integration and Support

- Custom fixturing and tooling design for your airframe envelope

- Post-processor and NC program integration with existing PLM/CAM systems.

- Onsite commissioning, operator training, and process validation packages.

- Remote diagnostics and preventive maintenance plans for continuous up time.

Measurable Outcomes our Customers See

- Faster program ramp-up: fewer hours from prototype to production baseline.

- Lower scrap and rework due to correct-first-time hole placement.

- Faster inspection cycles with digital reports tied to serialized parts.

- Better program traceability to support audits and supplier oversight.

Ready to see how KOMO fits your program?

If you manufacture CCAs or UASs and need a CNC solution that maps carbon-fiber bodies, drills, and countersinks inside the machine envelope, and delivers inspection reports automatically, let’s talk.